Oxygen Analyzer

MAXTEC

MAXO2+AE

เครื่องวิเคราห์ความเข้มข้นของออกซิเจน

Compatible with MAX-250E long-life sensors

5,000+ hours operation on 2 AA batteries

Large LCD characters to make it easier to read

Weekly calibration reminders

One-touch calibration & ON/OFF control

External Sensor Cable; 10 feet extended, 3 feet retracted

Oxygen Analyzer

MAXTEC

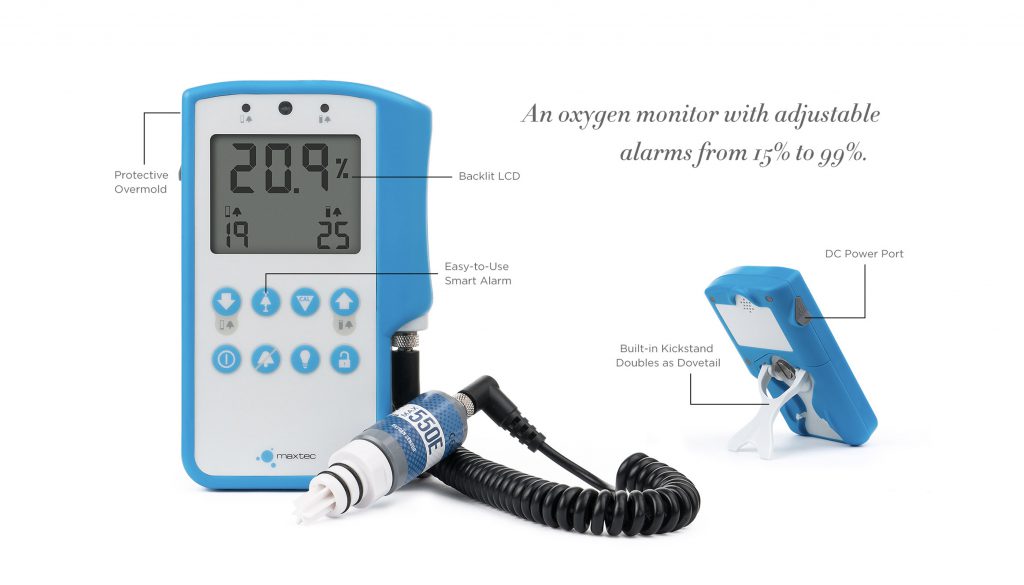

MAXO2 ME

เครื่องวิเคราห์ความเข้มข้นของออกซิเจน

Large, backlit LCD

Smart alarms auto-set at 3% +/- current reading

15% to 99% low alarm capabilities

Long battery life; up to 5,000 hours on four AA batteries

External Max-550E O2sensor

Built-in kickstand and dovetail

Oxygen Analyzer

MAXTEC

UltraMAXO2

เครื่องวิเคราห์ความเข้มข้นของออกซิเจน

Quick Set-Up & Readouts

The UltraMaxO2displays quick, easy-to-see readings with an overall much shorter setup time. The user only needs to connect the tubing from the gas sample inlet on the UltraMaxO2directly to the oxygen concentrator. The LCD screen on the UltraMaxO2displays large, clear numbers of the readings.

Reduced Cost of Ownership With The Ultrasonic Sensor

Because the UltraMaxO2does not require an oxygen sensor, there is no need to replace sensors over time. The built-in ultrasonic sensor is designed to last the life of the analyzer, unlike a traditional galvanic oxygen sensor. This helps maintain a low cost of ownership because the costs associated with maintenance and regularly replacing the sensor are alleviated.

Ability to Check Outlet Pressure

In some cases, medical device service technicians are required to record that they have calibrated the analyzer they are using to check equipment. The UltraMaxO2has a calibration verification button that verifies the unit is working correctly. When you hold down the button, it displays “cal ver” to confirm proper calibration, according to the product’s specifications. If there is an issue with the calibration (i.e. end of life, internal debris, etc.), it will display an error code to let the technician know there is an issue.

Some products used for oxygen concentrator servicing recommend that users calibrate their analyzers at 100% O2. This requires tanks or bottles of 100% oxygen and can become challenging to manage.

Using an ultrasonic solution like the UltraMaxO2means the gas is already calibrated and the calibration verification button eliminates the need for in-field calibration

No In-Field Calibration Required

In some cases, medical device service technicians are required to record that they have calibrated the analyzer they are using to check equipment. The UltraMaxO2has a calibration verification button that verifies the unit is working correctly. When you hold down the button, it displays “cal ver” to confirm proper calibration, according to the product’s specifications. If there is an issue with the calibration (i.e. end of life, internal debris, etc.), it will display an error code to let the technician know there is an issue.

Some products used for oxygen concentrator servicing recommend that users calibrate their analyzers at 100% O2. This requires tanks or bottles of 100% oxygen and can become challenging to manage.

Using an ultrasonic solution like the UltraMaxO2means the gas is already calibrated and the calibration verification button eliminates the need for in-field calibration